Texture Analysis SolutionsGelatin Bloom Strength Testing

Highlights

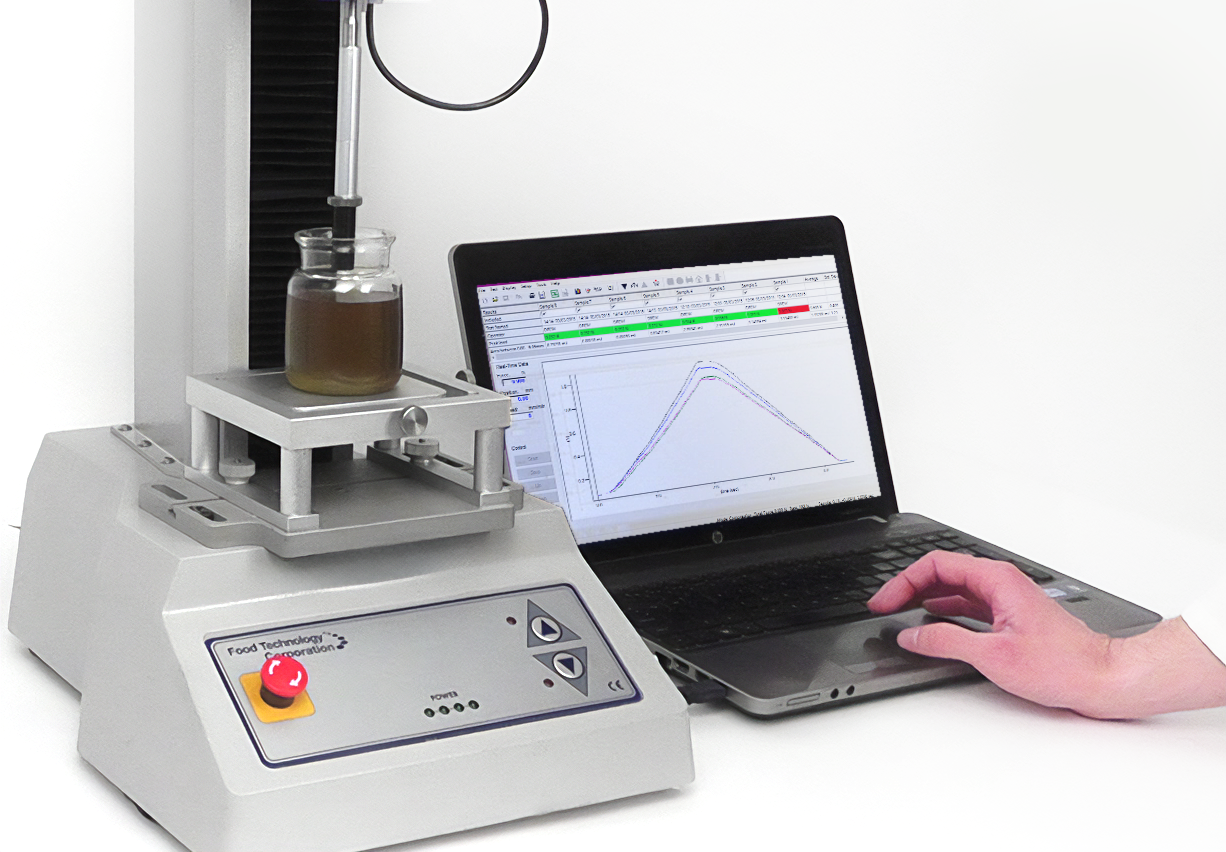

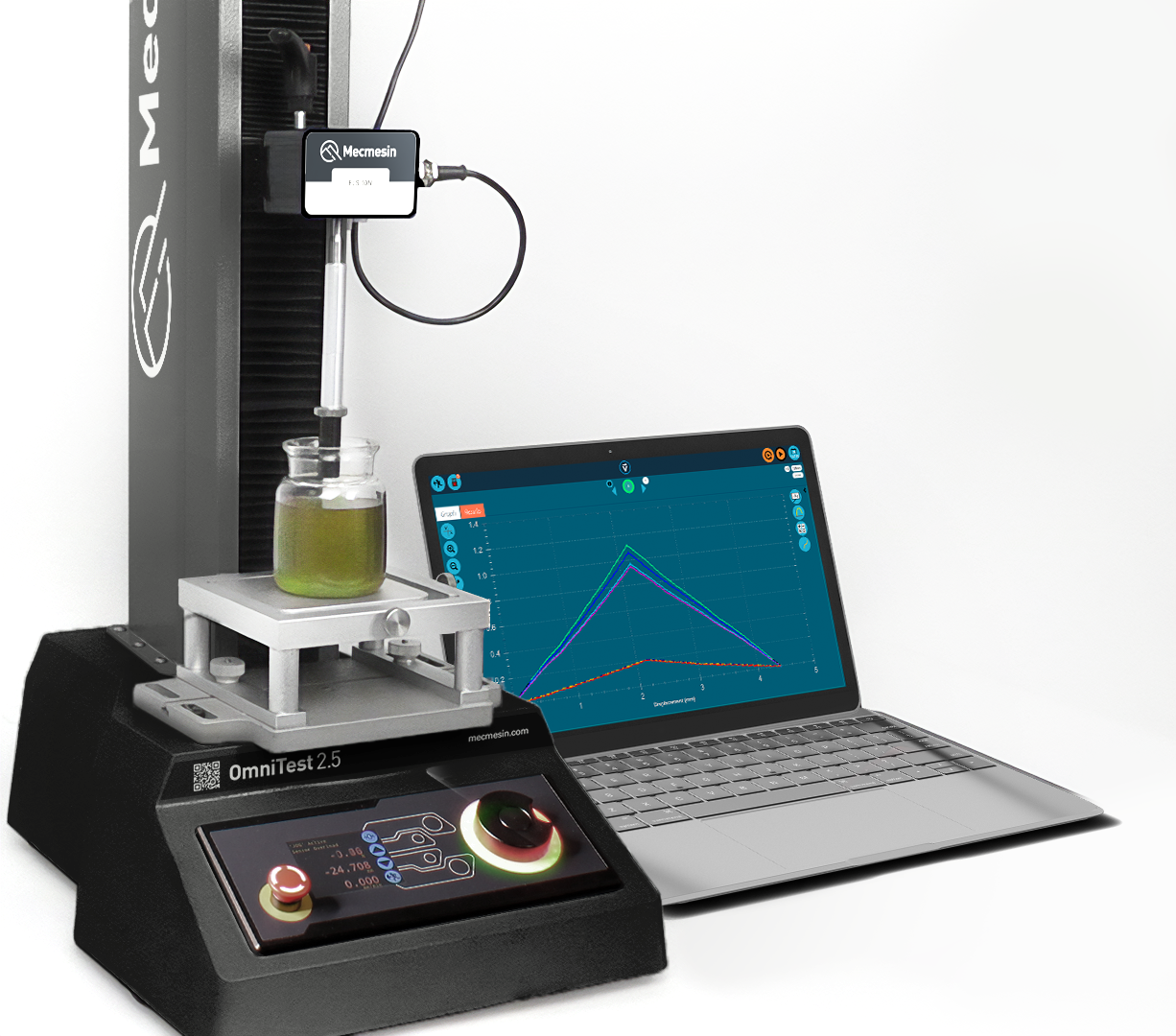

- Repeatable procedural method using a software-controlled texture analyzer to perform the steps

- Industry-standard cylinder probe to compress the surface to specific deflection and calculate the Modulus

- Measured hardness texture for ingredient qualification and gel commercial value

Samples of commercial gelatin (gelatine) were prepared and evaluated following recommendations from the Gelatine Manufacturers of Europe (GME) Monograph 2004 and ISO 9665.

Requirement

Gel strength is used by the world’s gelatin (gelatine) producers and end-users as a key quality indicator. Notable industries include food, cosmetics/pharma and similar semi-solid product manufacturers, adhesives and even photography. The functionality of gelatin is directly influenced by its strength, when prepared in accordance to the gelatin Bloom test. The Bloom strength value obtained is dependent upon sample preparation and evaluation. As higher Bloom values mean higher prices, the industry self-regulates itself. This helps guarantee accurate measurement of Bloom strength between the laboratories of customers and suppliers.

Key areas of standardization are:

- standardized test probe

- concentration and molecular weight

- temperature during mixing and tempering

- hydration times

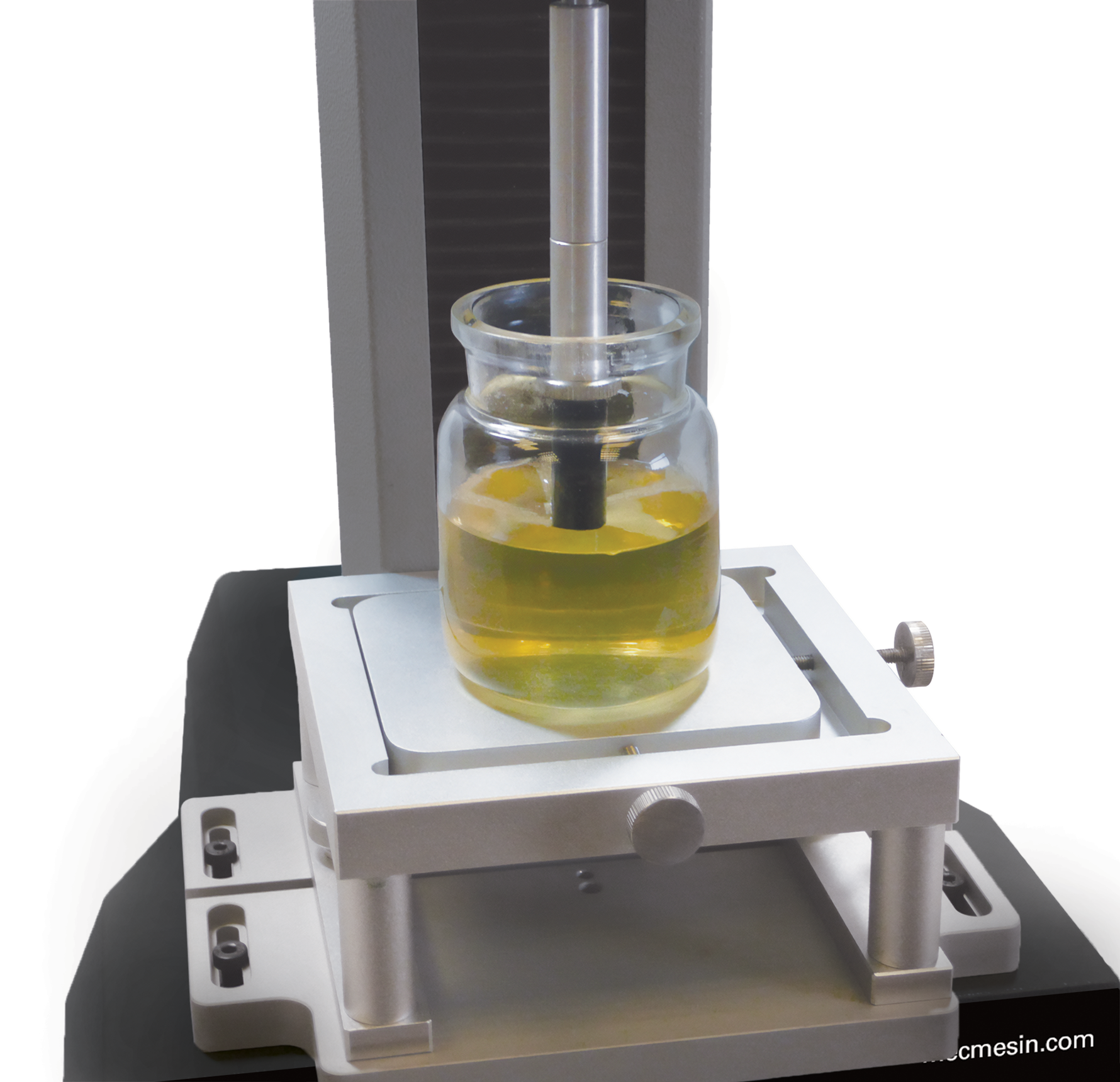

- test vessel dimensions

- instrumental accuracy and resolution

- test speed

- depth of penetration from trigger

Solution

Standard guidelines for sample preparation and gel strength measurement are fully established and enforced by the relevant geographic manufacturing bodies. The gelatin samples supplied were evaluated following relevant European recommendations for the concentration, preparation and tempering of gelatin gels.

The rigidity of the prepared gel was then tested with the AOAC 12.7mm diameter probe with no radius as per GME recommendations, July 1998, following traditional puncture principles.

Benefit

- Bloom - Optimisation of ingredient functionality and blend characteristics to the edible gelatins and industrial markets.

- Strength - Raw material control and quality payment between manufacturers, customers and processors.

- Elasticity / Modulus - Product formulation and development to gain maximum functionality from gel used.

Gel usage in industry

Gels and hydrocolloids—such as agar, gelatin, xanthan, and guar gum—play a vital role in the formulation of products across multiple industries, including food, cosmetics, personal care, and pharmaceuticals. Their unique texture-related properties make them essential for achieving the right consistency, stability, and functionality in a wide range of applications—from binding and thickening agents in food, to creams, shampoos, and toothpaste in personal care, and even in medical applications like ointments, capsules, and wound dressings.

To ensure consistency and performance, manufacturers need precise control over the gel texture parameters Bloom strength, elasticity, and rupture force. Texture analyzers enable reliable and repeatable measurement of these key characteristics, allowing producers to maintain high-quality standards and control formulations.