Texture Analysis SolutionsRaw almond cutting force

Highlights

- Objective comparison to quantify the effects of heat treatment

- Repeatable and quick test procedure to grade the product using a software-controlled texture analyzer

- Texture analysis calculations return important physical properties with the flexibility to add further detail

- Reporting back to upstream processing to optimize the full production cycle

Application

Several varieties of raw almonds were provided as part of a study to develop a method that would allow the processor to better understand how the products were going to behave in the slicing process.

Recently, new safety regulations had been put in place that require the almonds to go through a thermal process to ensure that they are free of any harmful microbiological contamination.

Problem

The downside of this heat treatment is that it can have an effect on how the product behaves in other parts of the entire production operation. The processor’s goal for this kind of texture testing is to have a better understanding of how certain changes in the process are going to affect the final product.

Solution

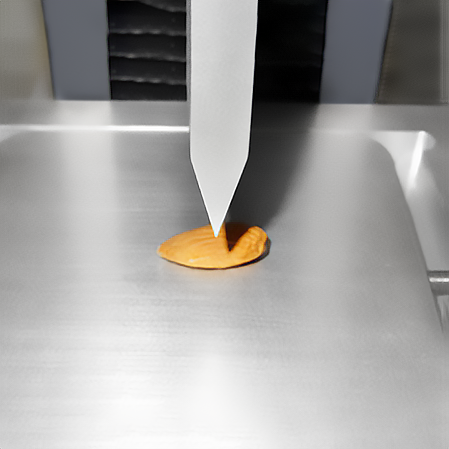

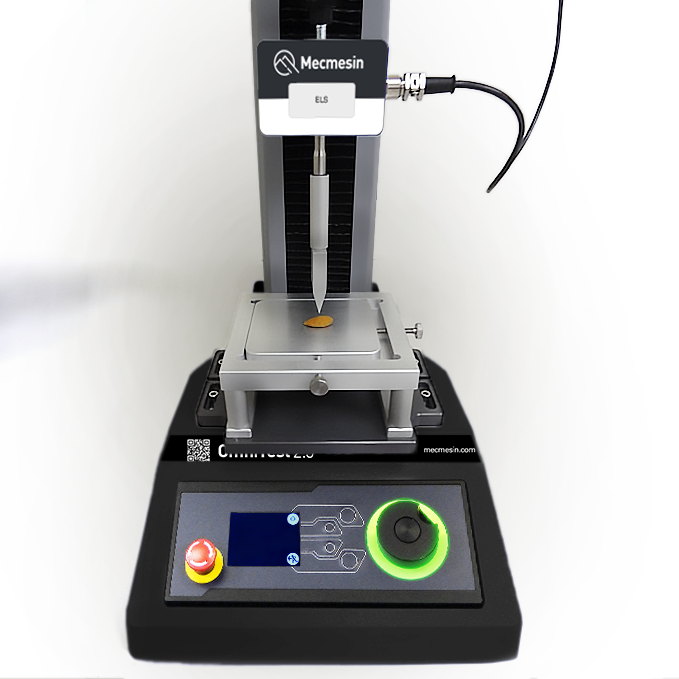

All testing was done using a Texture Analyzer fitted with a 500 N Intelligent Loadcell. The fixture used was the TMS Large Knife Edge. This particular fixture was chosen as the processor was interested in seeing how the new thermal process was going to affect how the samples sliced, the final product may be “chopped” and the end consumer may also slice or bite the whole raw almond. The TMS Large Knife Edge is designed to make precise cuts into any number of food products.

Prior to testing, the samples were allowed to equilibrate to ambient temperature (about 72°F). Once ready to test, a single whole almond was placed on the testing table. The blade moved down until it came into contact with the sample. It then moved an additional 2 mm at a speed of 250 mm/min. This distance was chosen as it was far enough to ensure that every sample fractured completely. Once the testing was completed, the texture analysis software was used to evaluate the force required for each sample to break.

Results

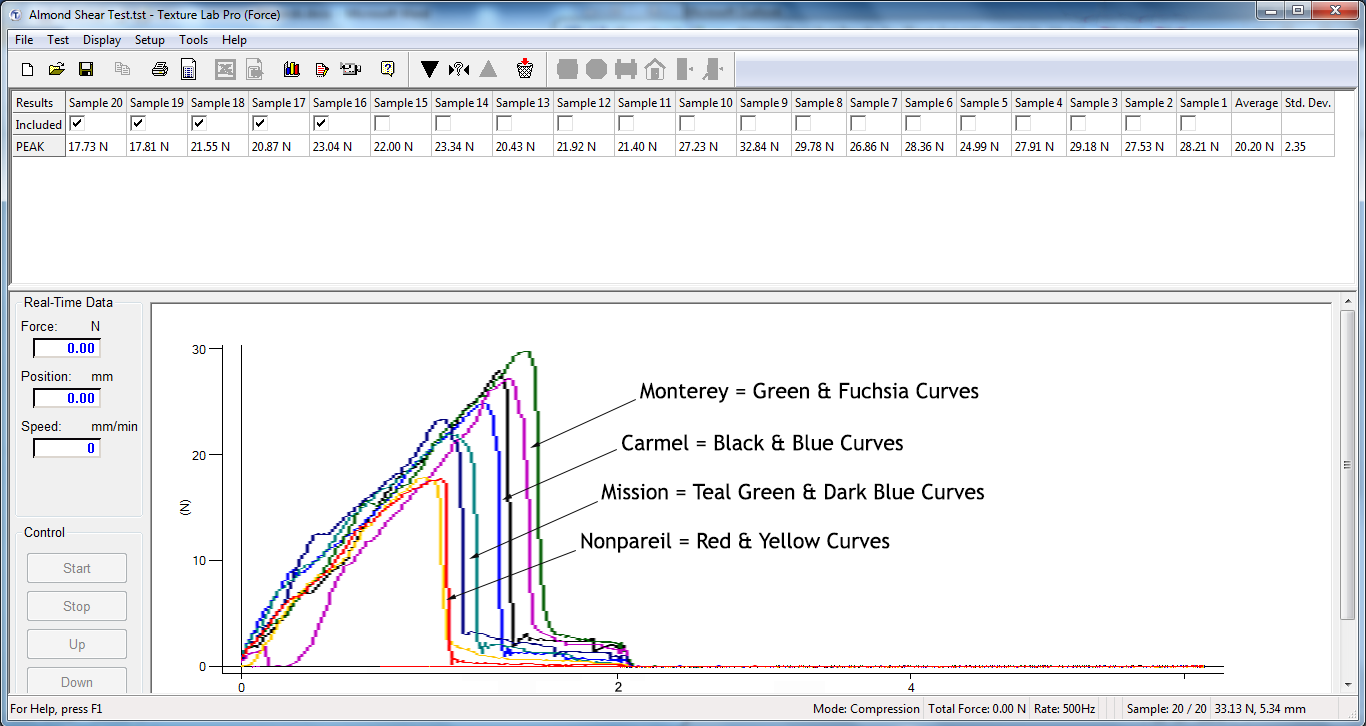

The graphical representation from the software of the test results for the eight samples is shown here as a function of force (Y-axis) over distance (X-axis).

While there is some overlap between the samples, it appears that there are 4 groupings that correspond with the 4 different almond variety samples that were sent by the processor. Higher peaks represent products that provide more resistance to the cutting blade used in the test. The processor should be able to correlate these findings with known slicing characteristics associated with each variety.

| Carmel | Peak (N) | Monterey | Peak (N) | Mission Peak | Peak (N) | Nonpareil | Peak (N) |

|---|---|---|---|---|---|---|---|

| Sample 1 | 28.2 | Sample 1 | 28.4 | Sample 1 | 21.4 | Sample 1 | 23.0 |

| Sample 2 | 27.5 | Sample 2 | 26.9 | Sample 2 | 21.9 | Sample 2 | 20.9 |

| Sample 3 | 29.2 | Sample 3 | 29.8 | Sample 3 | 20.4 | Sample 3 | 21.6 |

| Sample 4 | 27.9 | Sample 4 | 32.8 | Sample 4 | 23.3 | Sample 4 | 17.8 |

| Sample 5 | 25.0 | Sample 5 | 27.2 | Sample 5 | 22.0 | Sample 5 | 17.7 |

| Average: | 27.56 | Average: | 29.02 | Average: | 21.8 | Average: | 20.2 |

Significance

Based on the data gathered in the testing above, it can be determined that this test can be used by the processor to determine how the raw product is going to behave when sliced. Different varieties produce measurably distinct results. While a correlation study would have to be done by the producer—grading acceptable levels of quality, or rejection criteria—the texture analysis will provide the objective data to accomplish this. It is clear from the table of data, there are two groups. The Mission and the Nonpareil samples can be said to be softer, while the Carmel and the Monterey samples required more force to cut using the method developed. The processor will use this information to predict how the pasteurization process will affect the raw nuts when being sliced. Being able to calculate how the samples will behave during processing should reduce the amount of waste due to sub-standard product.