Texture Analysis SolutionsTofu Hot Dog Shear Resistance

Highlights

- Objective measurement of physical mouthfeel properties sensed in biting a meat-based hotdog to optimize a meat-free alternative

- Repeatable test method replicating the best sensory correlation for biting into meat using a software-controlled texture analyzer

- Precision compression probe to deform and rupture indentical test samples

- Quantified hardness texture correlated to the firmness of meat products using vegtarian, vegan an plant-based formulations

Situation

A meat processor wanted to develop a vegetarian alternative to its popular meat-based hotdog sausage using tofu as the base. Good correlation with the physical sensory properties of meat mouthfeel was required from an instrumental method.

Textural properties of vegetarian, vegan and plant-based alternatives to traditional meat-derived products are critical. This producer was successful in the local market for hotdog sales and wanted to repeat this success with their vegetarian offering, to leverage the trend for healthy options.

Method

Hardness to bite (shear resistance) and hardness to touch (perception of springiness) were identified as critical texture properties of the reconstituted-meat-based hotdogs. The bite feel is a typical factor for food science and in the case of a hotdog, handling is also involved by the consumer and a similar response to meat was necessary.

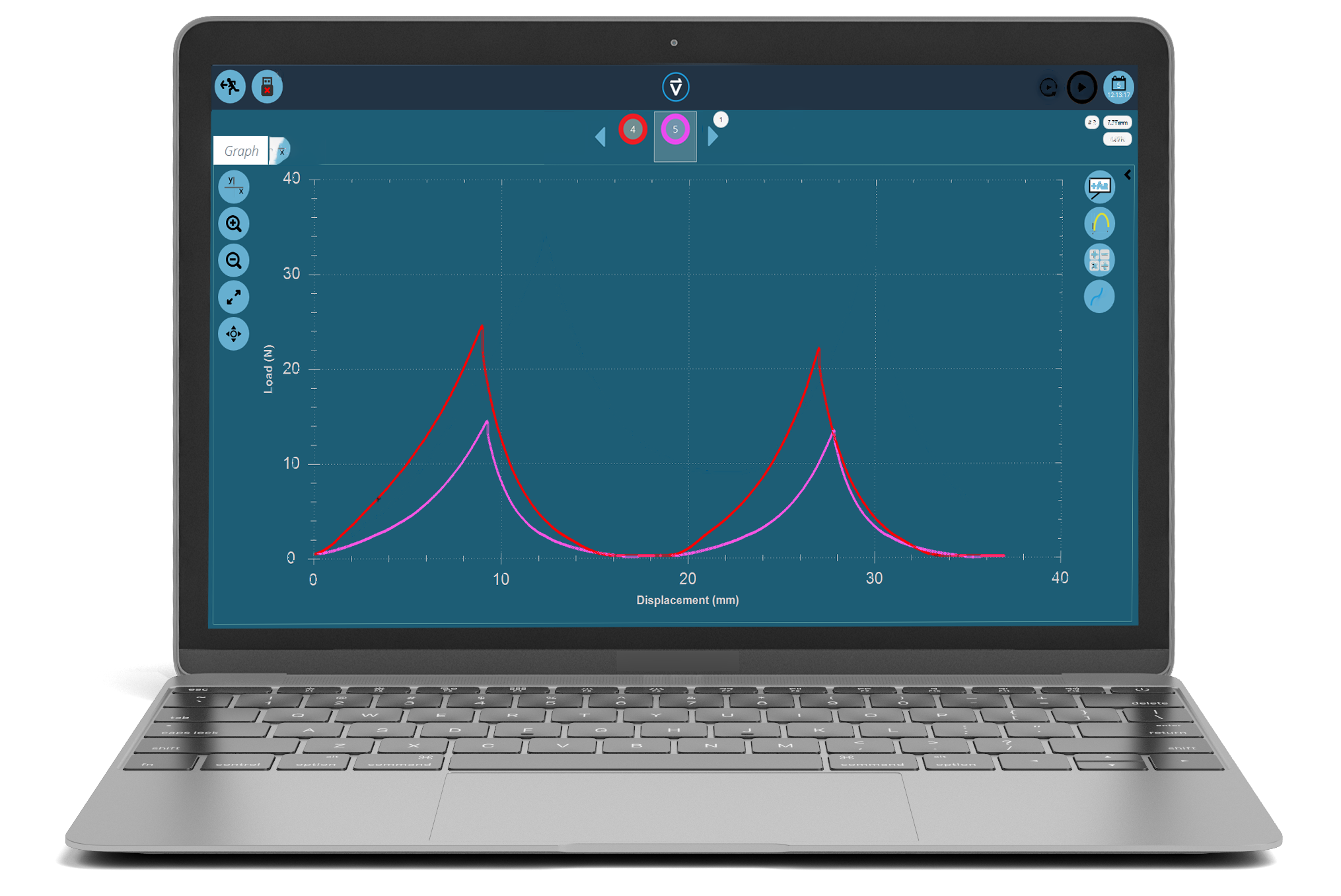

Instrumental texture analysis imitated these conditions through shear and compression testing. The cohesiveness and springiness attributes are determined by calculations from two compression cycles, which replicate the chewing of the sample.

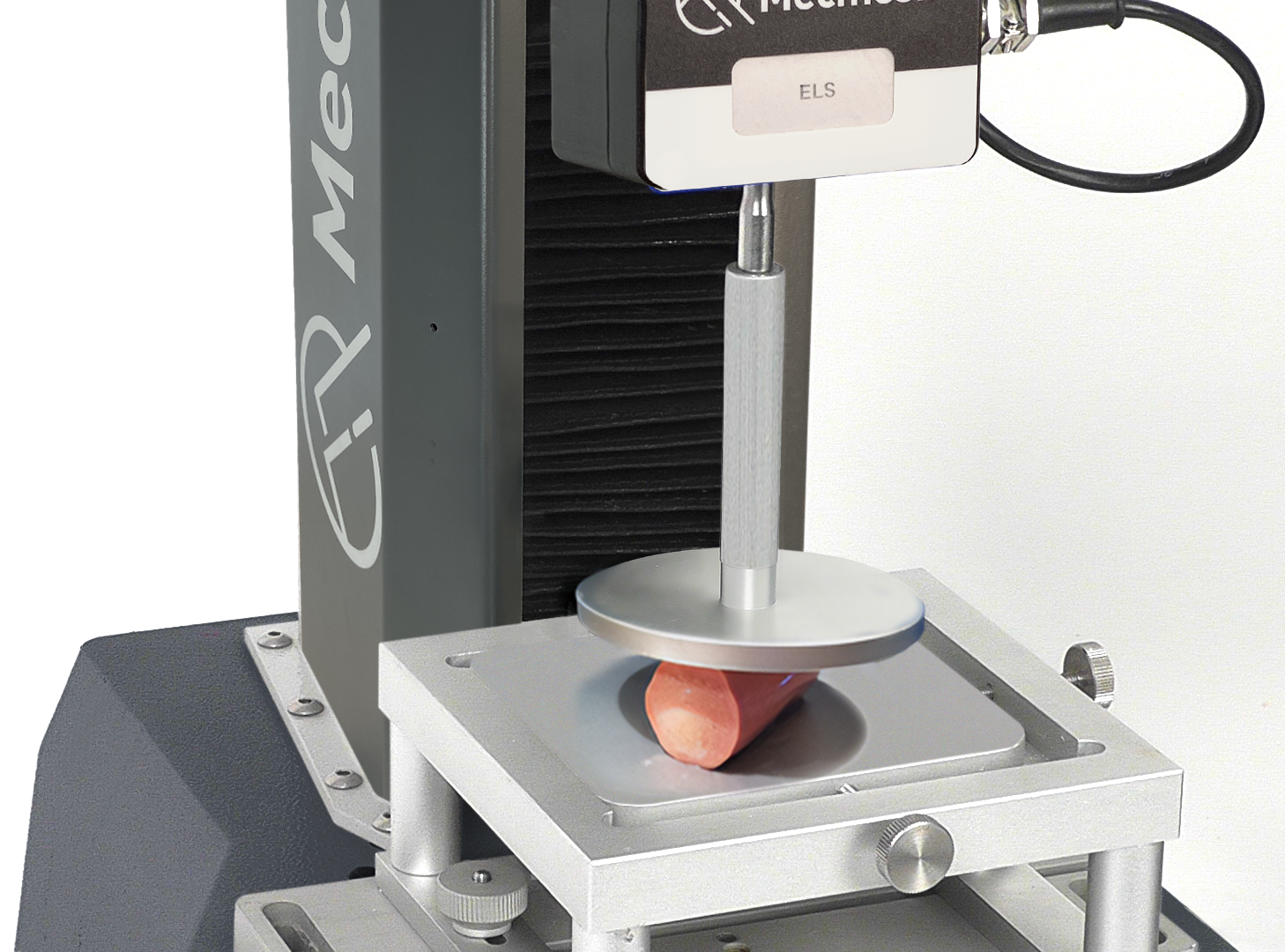

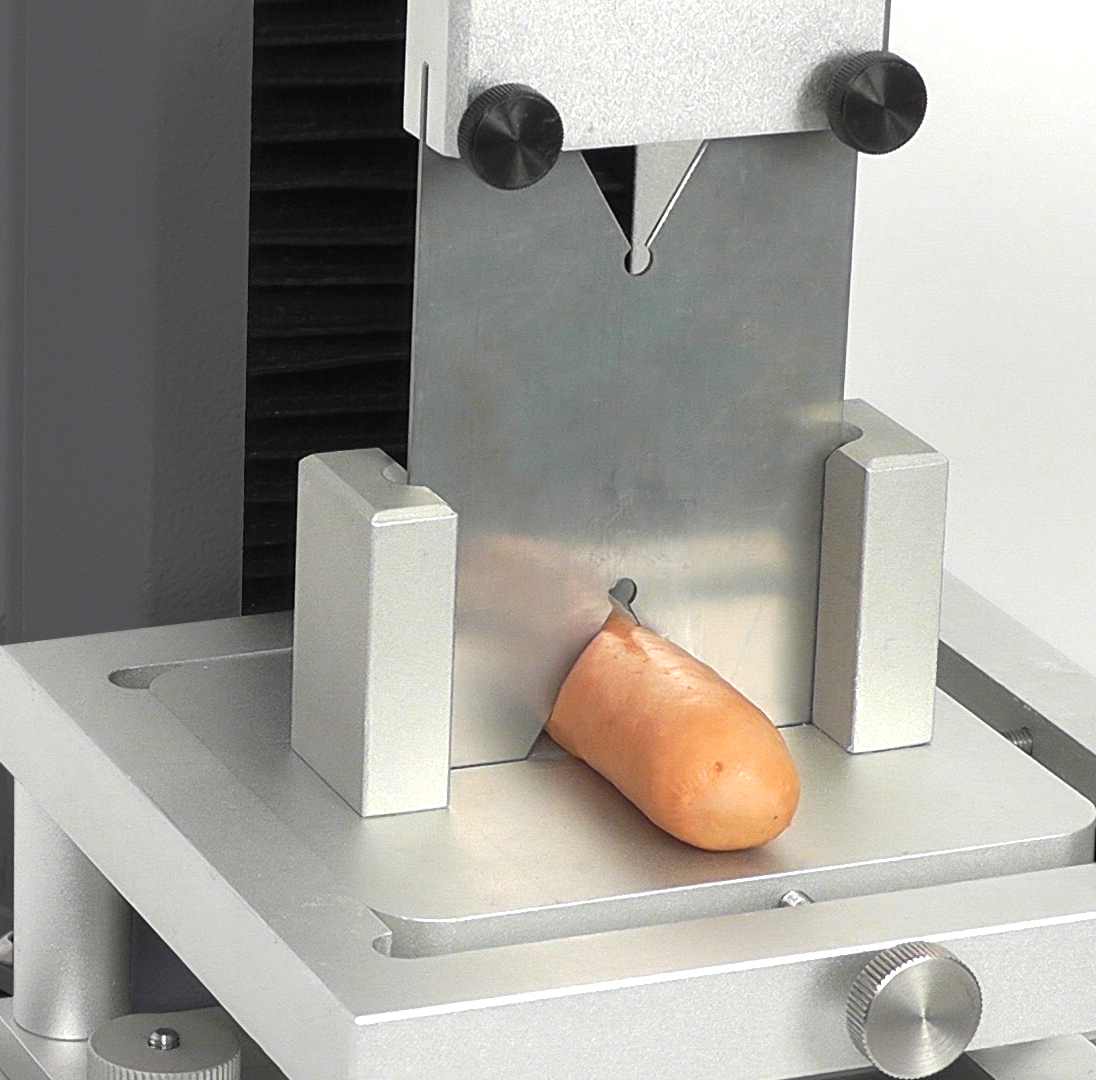

Shear test with blade

Shear testing involved a 1.2mm stainless steel blunt edge blade fixture. The test represents biting through the hotdog and follows the traditional Warner-Bratzler principles, employed within the meat industry as an indication of tenderness.

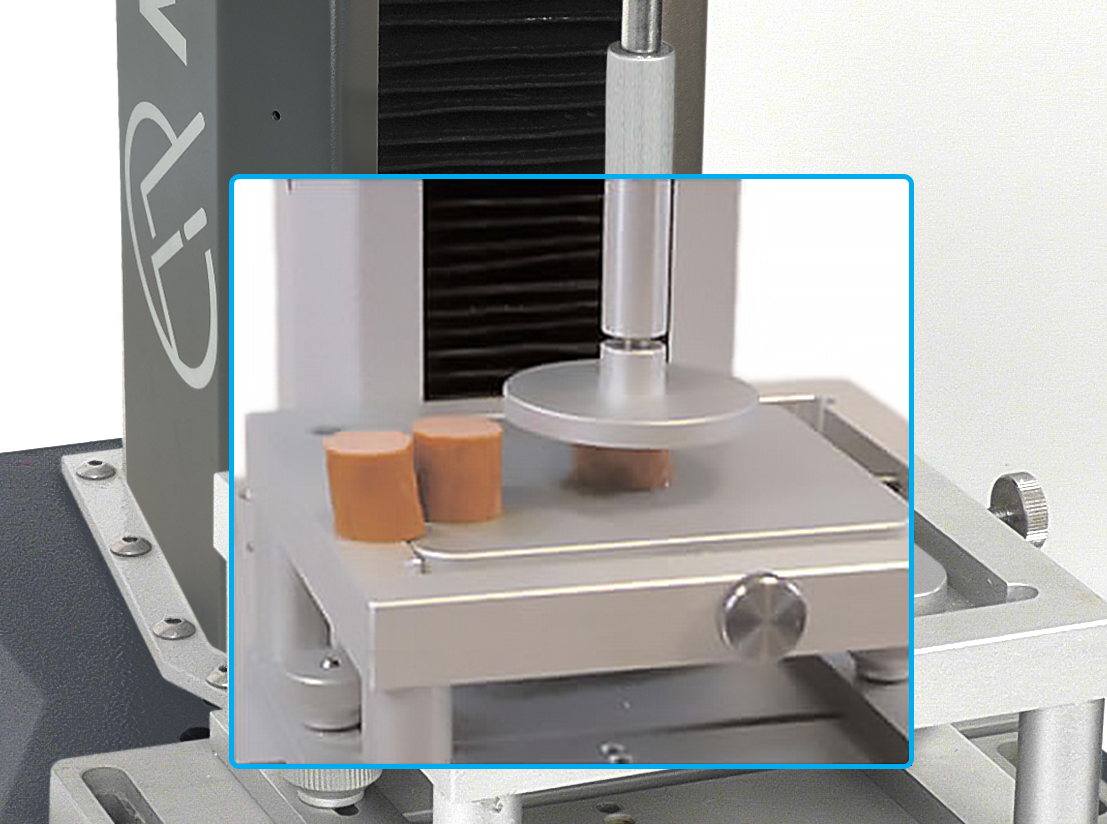

Compression TPA test with plate

The compression cycles method applies the principles of Texture Profile Analysis. The hotdog slices were compressed to 40% of the initial height and the physical strength was measured. The recovery of the sample after the first compression and then the subsequent deformation and energy absorbed are used in ratio calculations and attributed to cohesiveness.

Results

For this series of experiments, the tofu dog produced reasonably similar characteristics to the meat product. The veggie version was slightly firmer, but whether this is unacceptable would be determined by the processor. Control of the physical structure of the hotdog would impact the texture characteristics and changes to the formulation would now be easily evaluated.

The texture analysis calculations built in to VectorPro software enable the measured data (load, displacement, force) to be easily manipulated into formulae to calculate the standard sensory parameter definitions. In this was the food scientist can add further results to more completely evaluate the physical properties. Interchangeable fixtures allow this one texture analyzer system to be used to replicate further consumer or processing interactions with a familiar and extensible workflow.

Significance

A reproducible and objective method for measuring and comparing meat and vegetarian/vegan/plant-based products in the development process:

- Correlated with appropriate sensory properties

- Measure effects of process formulation changes during product matching

- Vegetarian product developed satisfactorily matches profile of target meat hotdog

OmniTest Texture AnalyzerUniversal software-controlled texture tester

The OmniTest Texture Analyzer is a flagship texture analysis instrument, for texture applications that require precise force, position and speed control. The PC-driven model has the flexibility to run the test routines on your choice of computer hardware.

This benchtop software-controlled system evaluate the mechanical properties of foods and other solid/semi-solid products that are judged by the end consumer by their physical sensory characteristics. These attributes relate to the sense of touch. Tactile interaction with the mouth or hands enable the customer to make a judgement on the quality of the product's texture.

Fitted with a suitable interchangeable fixture, the system replicates the natural kinaesthetic interaction (from biting to squeezing) and the results quantify the established texture profile attributes that correlate to mouthfeel, influencing perceived quality.

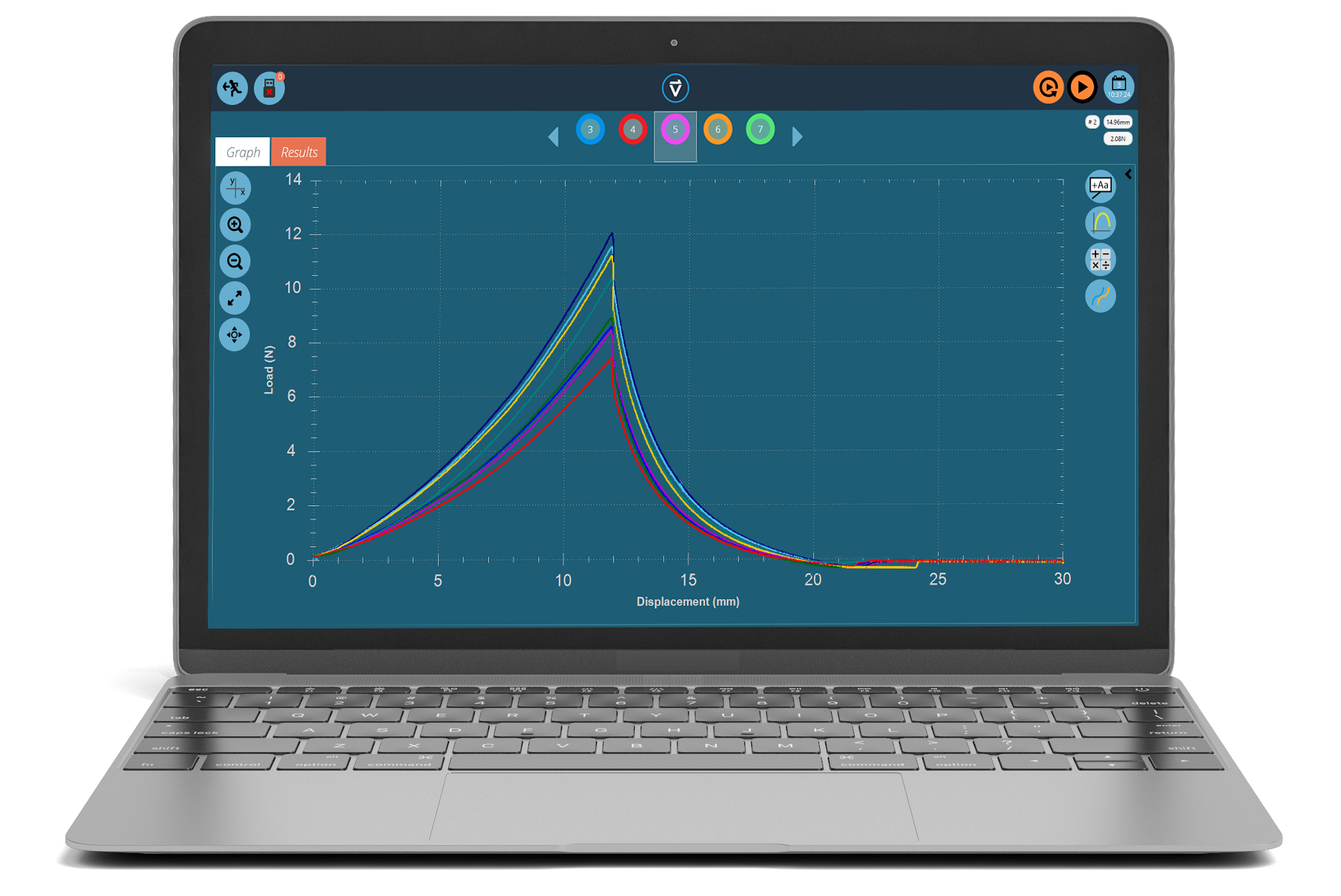

VectorPro software controls the OmniTest Texture Analyzer, via a connected PC, to apply the forces on the test sample, acquires the data and automatically calculates the results which correlate to the correct physical organoleptic sensory qualities. Peak forces, average forces, work can all be calculated from the graphical results to indicate the essential texture quality attributes of the sample material.

The OmniTest Touch Texture Analyzer is a flagship texture analysis instrument, for texture applications that require precise force, position and speed control. The standalone Touch model is configured with a touchscreen console that requires minimal operator training.

This standalone benchtop software-controlled system evaluate the mechanical properties of foods and other solid/semi-solid products that are judged by the end consumer by their physical sensory characteristics. These attributes relate to the sense of touch. Tactile interaction with the mouth or hands enable the customer to make a judgement on the quality of the product's texture.

Fitted with a suitable interchangeable fixture, the system replicates the natural kinaesthetic interaction (from biting to squeezing) and the results quantify the established texture profile attributes that correlate to mouthfeel, influencing perceived quality.

VectorPro software controls the OmniTest Texture Analyzer, via a connected touchscreen console PC, to apply the forces on the test sample, acquires the data and automatically calculates the results which correlate to the correct physical organoleptic sensory qualities. Peak forces, average forces, work can all be calculated from the graphical results to indicate the essential texture quality attributes of the sample material.

The OmniTest and OmniTest Touch Texture Analyzers make quality control testing in a production or laboratory environment a much simpler task, at an affordable price.

You can quickly determine the textural properties of bakery products, cereals, confectionary, snacks, dairy, fruit, vegetables, meat (or meat-free alternatives) and so much more. Pharma and cosmetic products such as creams and lotions can also be evaluated for their kinaesthetic feel on the hands.

Example applications