Texture Analysis SolutionsWet pet food firmness

Highlights

- Objective comparison to quantify physical properties of a wet pet food formulation

- Repeatable and quick test procedure to grade the product using a software-controlled texture analyzer

- Interchangeable fixtures to obtain data for a variety of deformation methods

- Quantified texture attributes correlated to acceptable mouthfeel firmness

Application

Wet pet food may be classified as 'canned' and includes products packaged in foil trays, pouches and similar sealed containers. They contain a high level of moisture, dependent on geographical market, generally above 60% and possibly as high as 80% water. The physical product is usually produced in the form of meat/protein chunks in gravy or jelly, casserole, paté and loaf formats. These foods are primarily marketed for cats and dogs but other carnivorous pets, such as ferrets, would be fed such menu items.

The physical makeup of wet and semi-moist foods can vary, the blend of protein, fats and water can form anything structure from a slurry to a more solid, granular mix. An essential ingredient (for obligate carnivores, like cats) is animal protein (typically fresh meat, poultry by-product meal, fish meal, meat and bone meal, blood meal or gelatin). Insect protein is a trend that is becoming more viable. Other solid ingredients may be added to provide a complete nutritional product, with veterinary formulations targeting support for lifestyle, ageing, sensitivities and other dietary requirements. Additives (vitamins, gelling agents and thickeners) plus further processing (sterilization to ensure safety and enhance shelf life) mean that there are many factors potentially influencing the texture and palatability of a wet pet food.

Problem

An unpalatable pet food can be more problematic than that of human food. The animal may need a specific diet (for health reasons) and have fewer options. Manufacturers need to control the texture as effectively as possible to market a successful product. Owners may have the choice to switch brands if their pet rejects their food. The chemical senses, olfactory (smell) and gustatory (taste) are highly influential in most animals, however, the physical texture plays an important part in acceptance as the physical attributes of a piece of raw meat are being substituted with a different material composition that must not be rejected.

Solution

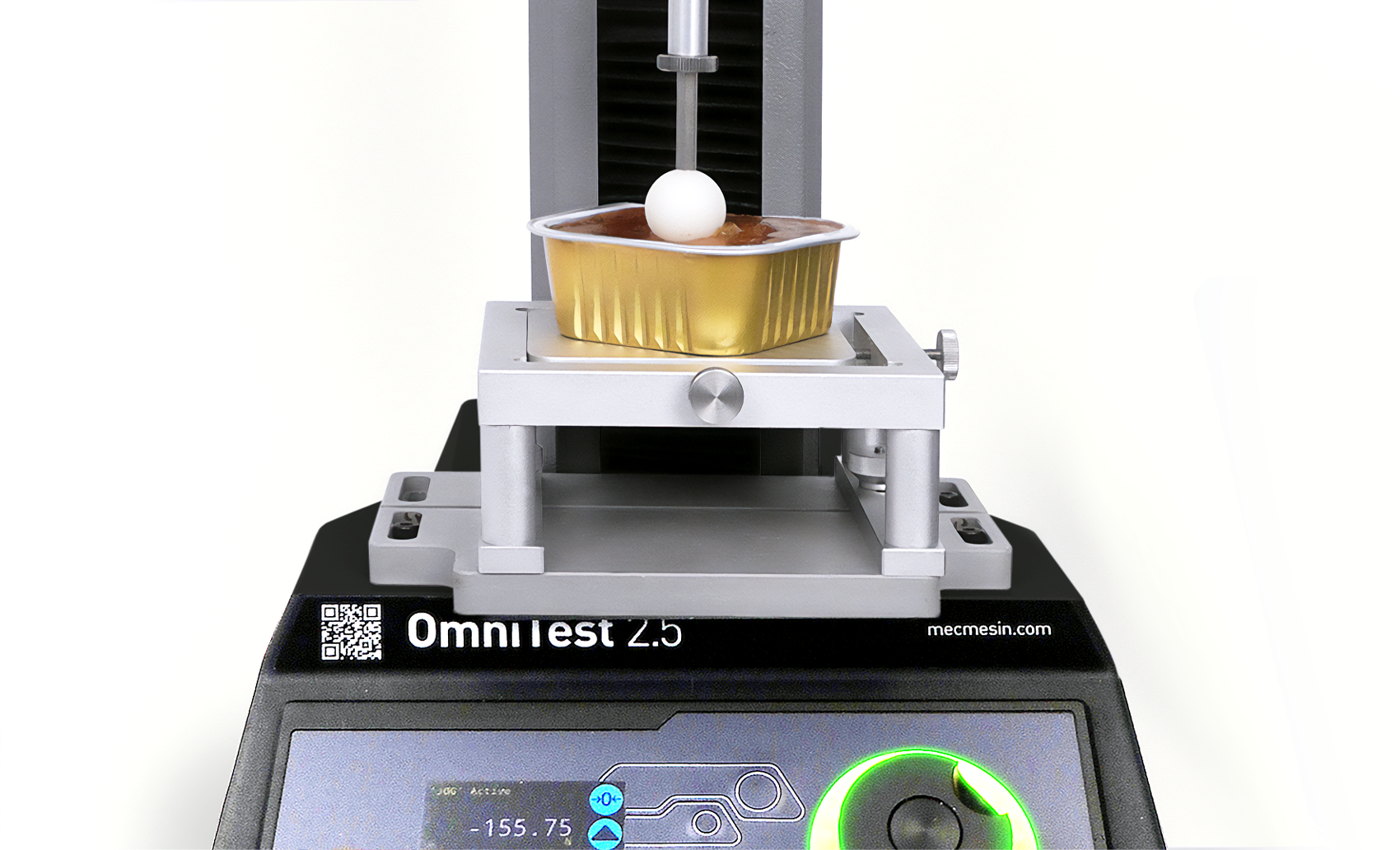

Once the pet has sniffed (and possibly licked) the food, the first mouthful is the next sensory interaction with the product. To replicate the resistance to this initial bite a spherical probe is used to compress the surface of the sample. The texture analysis program lowers the probe to lightly touch the sample surface, clears the force reading and then continues to press into the product to a depth of 5 mm.

The maximum force is the significant firmness marker and the software immediately returns the peak value, which can be assigned a visual pass or fail indication. A resistance characteristic similar to that of biting into meat would likely be ideal, with a particularly soft texture likely to prove difficult to 'bite' for a healthy animal, but potentially suitable for those with dental issues.

The graph shape and peak force indicate the firmness of the product and by correlating these data to practical testing of preferred firmness, the producer is able to measure and quality assure the final wet food product.

Further analysis

With the varieties of compositions available, tailored to appeal to different sized and species of animal, other texture analysis methods may be more appropriate or provide additional information to completely quantify the physical texture of the product. Smaller diameter probes will more accurately simulate a smaller and lighter initial bite and these other fixtures can help to optimize the correlation between real-world studies and the measured texture analysis results.

Replication of biting, some chewing and compression inside the mouth may be achieved with other interchangeable fixtures or a modified operational sequence. It is simple to implement two compression strokes (a TPA analysis technique) to further characterize the breakdown of the formulation upon multiple chews. To simulate penetrating further into the product, smaller probes are used.

The pet owner may slice or mash the product before serving and this may influence the perceived suitability of the solid/semi-solid matrix. Bulk analysis is an ideal method to measure the overall averaged firmness in a product containing chunks of meat, added vegetables or grains, where the material is non-homogeneous. The same texture analyzer applying a similar but refined test program can easily measure the comparative performance.

OmniTest Texture AnalyzerUniversal software-controlled texture tester

The OmniTest Texture Analyzer is a flagship texture analysis instrument, for texture applications that require precise force, position and speed control. The PC-driven model has the flexibility to run the test routines on your choice of computer hardware.

This benchtop software-controlled system evaluate the mechanical properties of foods and other solid/semi-solid products that are judged by the end consumer by their physical sensory characteristics. These attributes relate to the sense of touch. Tactile interaction with the mouth or hands enable the customer to make a judgement on the quality of the product's texture.

Fitted with a suitable interchangeable fixture, the system replicates the natural kinaesthetic interaction (from biting to squeezing) and the results quantify the established texture profile attributes that correlate to mouthfeel, influencing perceived quality.

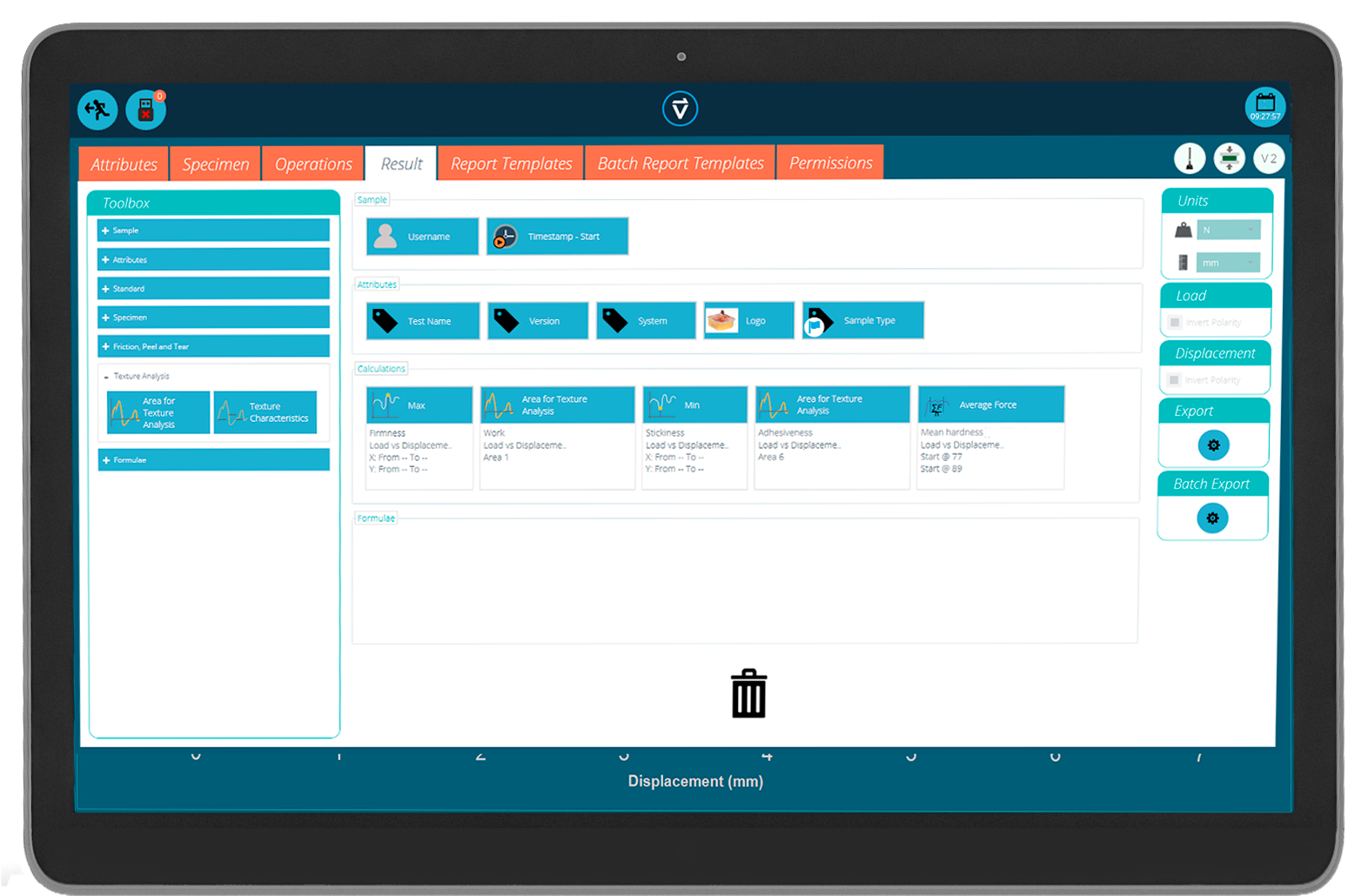

VectorPro software controls the OmniTest Texture Analyzer, via a connected PC, to apply the forces on the test sample, acquires the data and automatically calculates the results which correlate to the correct physical organoleptic sensory qualities. Peak forces, average forces, work can all be calculated from the graphical results to indicate the essential texture quality attributes of the sample material.

The OmniTest Touch Texture Analyzer is a flagship texture analysis instrument, for texture applications that require precise force, position and speed control. The standalone Touch model is configured with a touchscreen console that requires minimal operator training.

This standalone benchtop software-controlled system evaluate the mechanical properties of foods and other solid/semi-solid products that are judged by the end consumer by their physical sensory characteristics. These attributes relate to the sense of touch. Tactile interaction with the mouth or hands enable the customer to make a judgement on the quality of the product's texture.

Fitted with a suitable interchangeable fixture, the system replicates the natural kinaesthetic interaction (from biting to squeezing) and the results quantify the established texture profile attributes that correlate to mouthfeel, influencing perceived quality.

VectorPro software controls the OmniTest Texture Analyzer, via a connected touchscreen console PC, to apply the forces on the test sample, acquires the data and automatically calculates the results which correlate to the correct physical organoleptic sensory qualities. Peak forces, average forces, work can all be calculated from the graphical results to indicate the essential texture quality attributes of the sample material.

The OmniTest and OmniTest Touch Texture Analyzers make quality control testing in a production or laboratory environment a much simpler task, at an affordable price.

You can quickly determine the textural properties of bakery products, cereals, confectionary, snacks, dairy, fruit, vegetables, meat (or meat-free alternatives) and so much more. Pharma and cosmetic products such as creams and lotions can also be evaluated for their kinaesthetic feel on the hands.

Example applications